AG Thermochemische Umwandlung

Das Ziel der Aktivitäten der Gruppe für thermochemische Umwandlung ist die Erforschung und Optimierung der hydrothermalen Karbonisierung (HTC), der hydrothermalen Humifizierung (HTH) und der Pyrolyseprozesse zur Herstellung von Hydrochar, Huminstoffen und Pyrochar. Der Schwerpunkt liegt auf der Anwendung dieser Materialien zur Bodenverbesserung, einschließlich der Erhöhung der Wasserrückhaltefähigkeit, der Kationen- und Anionenaustauschkapazität und der langfristigen Kohlenstoffspeicherung. Darüber hinaus wird die Gruppe die Adsorption von Nährstoffen und Schadstoffen aus Wasser, Boden und Tierdung sowie die Reinigung von kohlenstoffhaltigen Materialien für fortgeschrittene Anwendungen wie Membranen und Energiespeicherung untersuchen. Die Modellierung und Optimierung helfen dabei, die Prozesse zu skalieren und von Chargen- zu kontinuierlichen Prozessen überzugehen.

Hydrothermale Karbonisierung (HTC) und Humifizierung (HTH)

HTC wird bei erhöhten Temperaturen von typischerweise 180 bis 250 Grad Celsius durchgeführt und stellt eine umweltfreundliche Technologie zur Umwandlung von feuchten Rückständen in Hydrochar dar. Hydrochar findet Anwendung in der Bodenverbesserung, Umweltsanierung, Biokraftstoffproduktion und Energiespeicherung.

HTH beschleunigt die Produktion von Huminstoffen aus Biomasse – ein komplexer Prozess, der in der Natur normalerweise Jahre dauert – und führt ihn innerhalb weniger Stunden durch, was erhebliche Vorteile für die Bodenverbesserung mit sich bringt. Die Produkte werden hauptsächlich in der Landwirtschaft, zur Bodenverbesserung und für verschiedene Umweltanwendungen eingesetzt.

Batch- und kontinuierliche hydrothermale Reaktoren

Zu den verfügbaren hydrothermalen Anlagen gehören Hochdruck-Batch-Reaktoren (150 ml, 1 l, 18,75 l) sowie ein kontinuierlicher Reaktor von Artec. Weitere Details zu den Nachbearbeitungsschritten finden Sie unter Biochar-Labor.

Pyrolyseprozess

Pyrolyse ist ein thermischer Zersetzungsprozess, der unter Ausschluss von Sauerstoff stattfindet. Dabei werden kohlenstoffreiche Materialien wie Biomasse oder organische Abfälle hohen Temperaturen ausgesetzt, die in der Regel zwischen 300 und 800 Grad Celsius liegen. Eines der wichtigsten Ergebnisse der Pyrolyse ist die Umwandlung trockener kohlenstoffhaltiger Materialien in stabile Kohlenstoffformen, die als Pyrochar bekannt sind. Dieses Pyrochar hat ein breites Anwendungsspektrum, darunter die Verwendung zur Bodenverbesserung, zur Herstellung von Biokraftstoffen und für verschiedene Umweltanwendungen. Darüber hinaus kann Pyrochar technisch verändert oder aktiviert werden, um seine Eigenschaften zu verbessern, sodass es für Katalyse, Adsorptionsprozesse und Energiespeicherung geeignet ist.

Pyrolysereaktoren

Pyrolyse (diskontinuierlich und kontinuierlich)

Zu den verfügbaren Pyrolyseanlagen gehören diskontinuierliche Pyrolyse-Muffelöfen und kontinuierliche Reaktoren, darunter ein Drehrohrofen, ein Carbon Twister sowie eine Pyrolyseanlage von BIOMACON. Weitere Details zu den Nachbearbeitungsschritten von Pyrochar finden Sie unter Biochar-Labor.

Gruppenaktivitäten:

1- Prozessverständnis und Skalierung (Modellierung und Optimierung)

Die Entwicklung empirischer und thermochemischer Modelle, die ein tieferes Verständnis komplexer Reaktionen ermöglichen, ist ein entscheidender Schritt zur Skalierung thermochemischer Umwandlungsprozesse. Dieser Fortschritt erstreckt sich auch auf die kinetische Modellierung, insbesondere in den Bereichen hydrothermale Karbonisierung (HTC) und hydrothermale Humifizierung (HTH), wo Vorhersagemodelle unsere Fähigkeit zur Optimierung dieser Prozesse verbessern. Darüber hinaus verändert die Integration intelligenter Modellierungstechniken die Prozessoptimierung und ermöglicht effizientere und nachhaltigere Produktionsmethoden. Diese Modelle helfen bei der Vorhersage des Systems und beim Übergang von traditionellen Chargenprozessen zu kontinuierlichen Prozessen, was eine höhere Effizienz und weniger Abfall verspricht.

- Entwicklung empirischer und thermochemischer Modelle.

- Kinetische Modellierung von HTC und HTH.

- Intelligente Modellierung zur Prozessoptimierung.

- Übergang von Chargen- zu kontinuierlichen Prozessen.

- Intelligente integrierte Bioraffinerien

2- Herstellung von technischem Pyrochar und Hydrochar sowie künstlichen Huminstoffen für verschiedene Anwendungen

a) Bodenverbesserung und Kohlenstoffspeicherung:

- Untersuchung der Wechselwirkung von kohlenstoffreichen Substanzen mit Boden und Pflanzen.

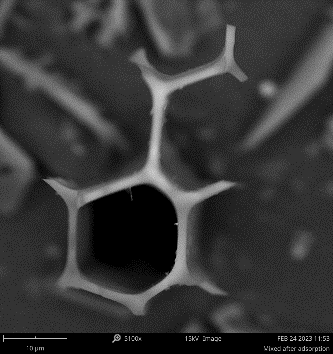

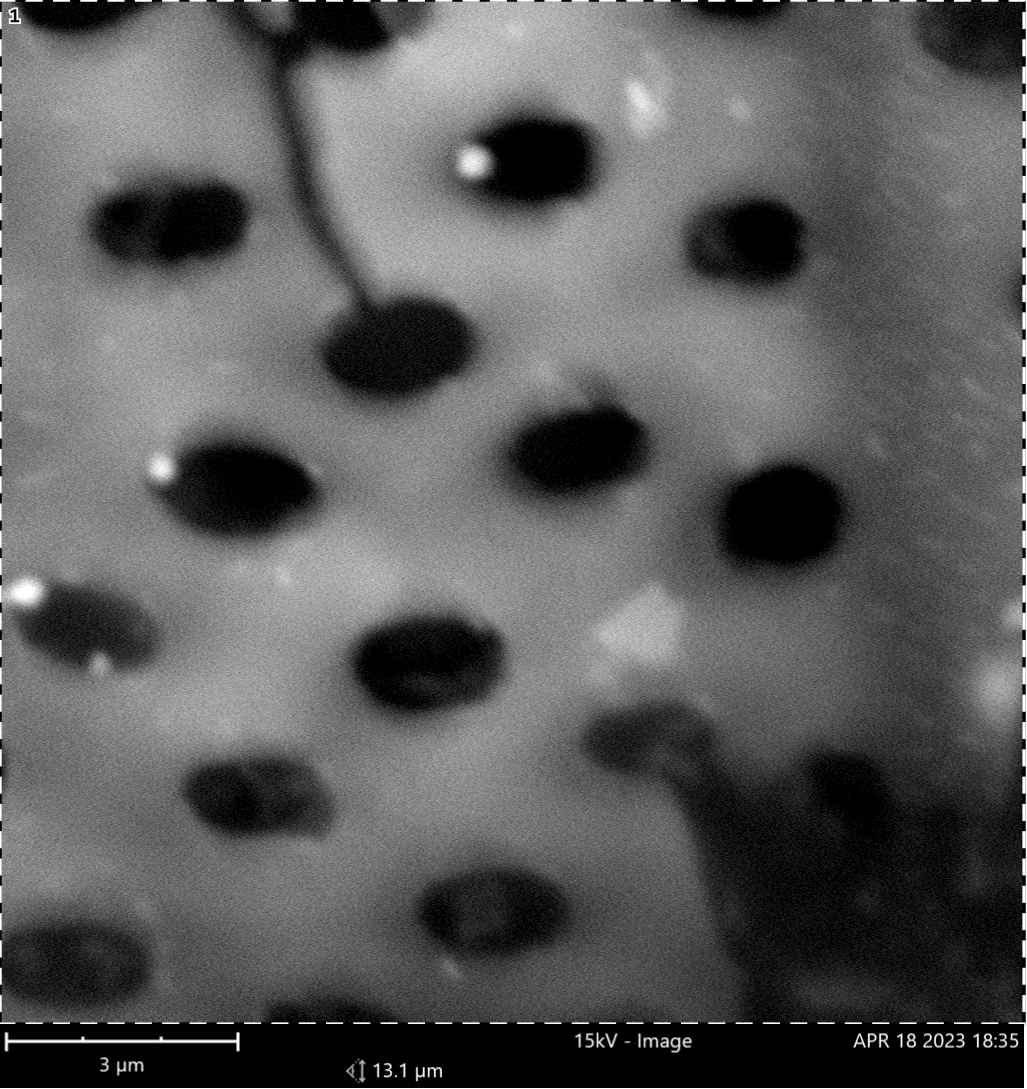

- Entwicklung poröser Pyrochar-Partikel zur Bodenverbesserung.

- Herstellung von technischem Pyrochar mit hoher Kohlenstoffspeichereffizienz.

- Bewertung des Potenzials kohlenstoffreicher Materialien als Kohlenstoffsenken.

b) Nährstoffrückgewinnung und Schadstoffentfernung:

- Oberflächenmodifizierung und Funktionalisierung von Hydrochar und Pyrochar.

- Entwicklung von Pyrochar und Hydrochar für die selektive Adsorption von Nährstoffen und Schadstoffen.

- Untersuchung der Adsorptionskapazität für Nährstoffe und Schadstoffe in Wasser, Boden und Gülle.

- Erforschung von Anwendungen für die Wasser- und Bodensanierung.

c) Reinigung von kohlenstoffhaltigen Materialien und fortgeschrittene Anwendungen:

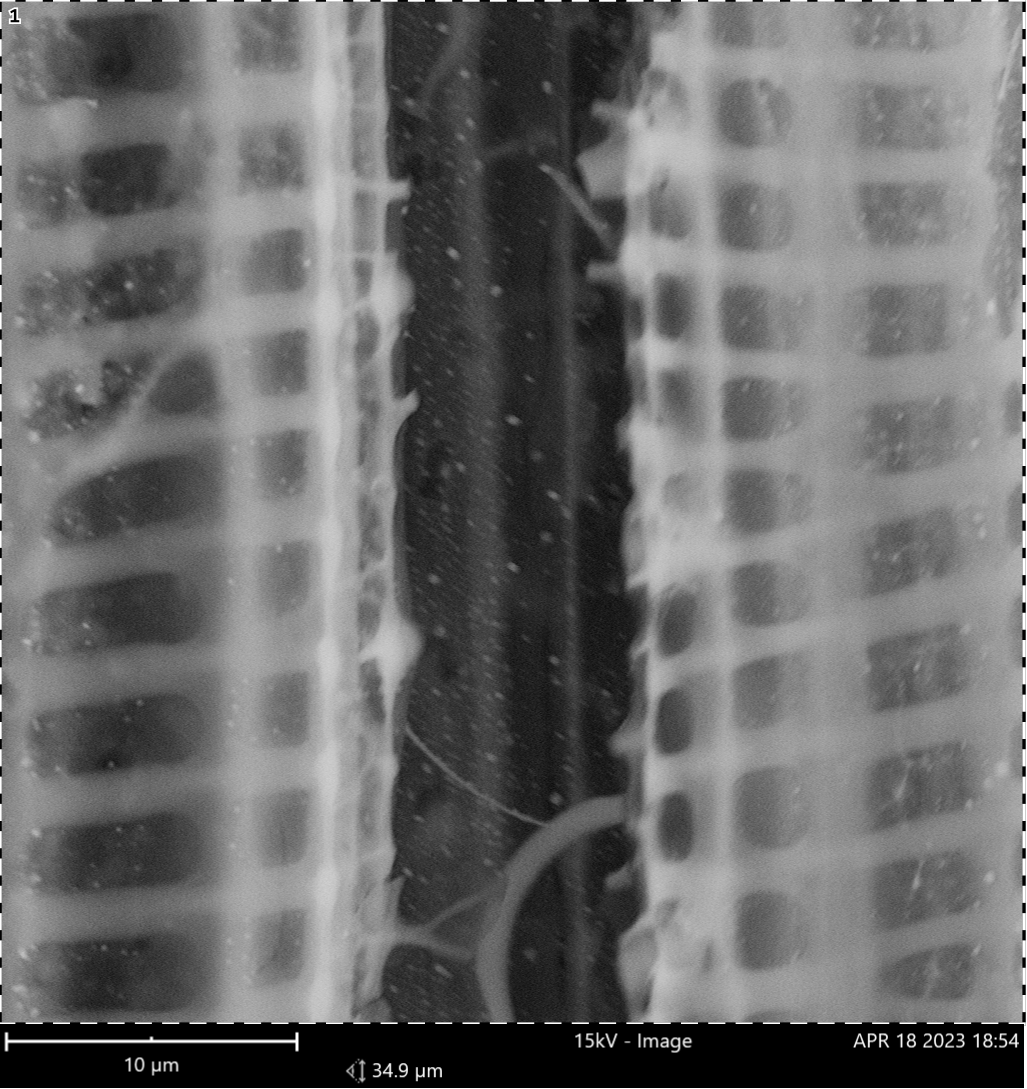

- Reinigung und Dotierung von kohlenstoffhaltigen Materialien für fortgeschrittene Anwendungen wie Membrantechnologie und Katalyse.

- Entwicklung maßgeschneiderter Kohlepartikel für spezifische Anwendungen.

- Regeneration und Wiederverwendung von verbrauchten kohlenstoffbasierten Materialien.

- Entfernung von Schadstoffen, einschließlich PAHs und anorganischen Elementen, aus kohlenstoffhaltigen Materialien.

- Synthese von kohlenstoffbasierten Katalysatoren

- Alternative Katalysatoren für die hydrothermale Humifizierung

- Katalytische Anwendung von Biokohle und Hydrokohle zur Energieerzeugung

3- Integriertes Reststoffmanagement:

Im Rahmen des integrierten Reststoffmanagementprogramms verfolgt die Gruppe das Ziel, organische Abfälle und Reststoffe aus anderen Prozessen zu nutzen und in eine stabilere Form von Kohlenstoff umzuwandeln. Die resultierenden Produkte können je nach ihren Eigenschaften wieder in den Prozess zurückgeführt werden, aus dem sie stammen, um die Ausbeute zu erhöhen und/oder die Produkte zu reinigen. Die Produkte können für andere Zwecke verwendet werden, z. B. für die Herstellung von Biokraftstoffen, für Boden- und Umweltanwendungen.

4- Zusammenarbeit mit der Industrie

Die Aktivitäten unserer Gruppe gehen über die Forschung hinaus, da wir aktiv mit unseren Industriepartnern zusammenarbeiten. Wir sind bestrebt, auf ihre spezifischen Bedürfnisse einzugehen und bieten Unterstützung in Bereichen wie Prozessentwicklung, Produktcharakterisierung, Prozessoptimierung und Skalierung. Dieser kooperative Ansatz stellt sicher, dass unsere Forschung nicht nur den wissenschaftlichen Kenntnisstand erweitert, sondern auch direkt zu praktischen Anwendungen und zum Erfolg unserer Industriepartner beiträgt.

5- Charakterisierung und Analyse thermochemischer Umwandlungsprodukte:

- Elementaranalyse, ICP-OES und Nährstoffgehalt (P und N)

- Analyse gasförmiger Produkte aus Pyrolyse- und HTC-Prozessen

- HPLC für organische Säuren, Aromaten und Zucker in festen und flüssigen Produkten

- Extraktion und Analyse von Huminstoffen

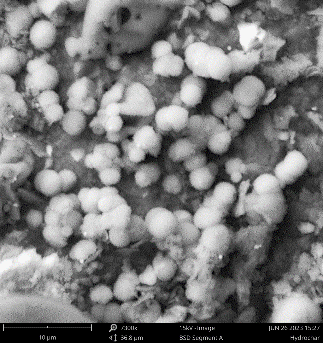

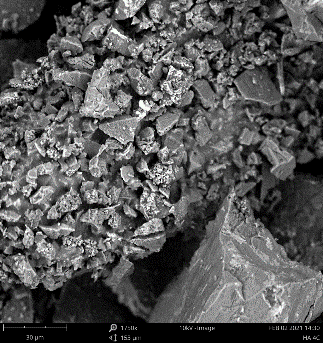

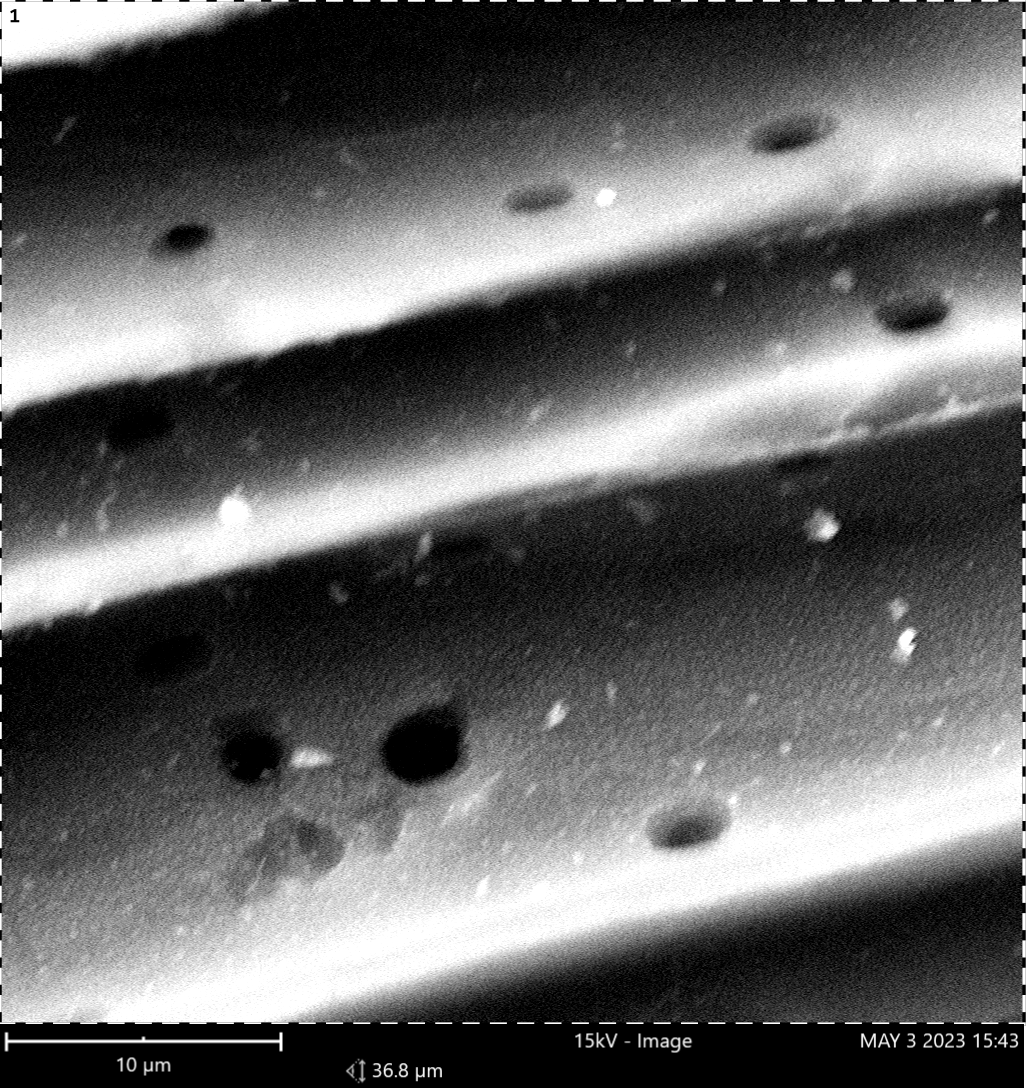

- Charakterisierung durch FTIR, BET-Oberfläche, Porengrößenanalyse, TGA, SEM-EDX

- Rezistenz und Kohlenstoffspeicherpotenzial von Biomasse, Hydrochar, künstlichen Huminstoffen und Biokohle

- Wasseraufnahmefähigkeit von Biomasse, Hydrochar, künstlichen Huminstoffen und Biokohle

Mitarbeiter*innen der AG

Postdoktoranden:

Opeyemi Ayodejl Akogun

Huyen Chau Dang

Doktoranden:

Daniela Moloeznik Paniagua

Saman Ghobadian

Mohaddesseh Ebrahimi

Masterstudierende:

Jonas Alexis Buchholz

Wei-Che Hsiao

Niloufar Hamzehlou

Gastwissenschaftler:

Prof. Dr. Fabiano Bisinella Scheufele

Prof. Dr. Caroline Ribeiro

Techniker

Dipl.-Ing. (FH) Marcus Fischer

Imke Handke