Rethinking packaging.

Maintaining quality - reducing losses.According to FAO estimations, fruit and vegetables account for 45-50% of global food losses. The loss in the post-harvest period is particularly severe, as it also means that the inputs used for the production (land use, energy, etc.) are lost.

Fresh products such as fruit and vegetables are metabolically active post harvest. They consume oxygen, while generating heat, carbon dioxide, water vapour and aromatic compounds, and therefore spoil easily. In order to be able to prevent quality losses in the post-harvest by means of improved process design, we first need to understand the physiological and physical properties of the respective products and know how they respond to certain environmental influences.

Packaging: Reducing food losses, but producing waste?

An important method for maintaining the quality of fresh products is packaging. Packaging creates increasing waste piles and pollutes the environment. However, packaging protects sensitive foods such as raspberries, strawberries or salad from mechanical impacts. It also minimizes hygienic risks and helps to reduce transpiration and mass losses, for example in leafy vegetables. Thus, packaging offers many advantages and helps to extend the shelf life of perishable products and to reduce food losses.

Customized packaging design - new materials

Packaging is to protect the product and extend its shelf life by providing the optimum gas composition and moisture in the packaging. Our goal is to better understand the mechanisms of water vapor and condensation dynamics in packaged fresh products and to develop optimized packaging on this basis.

For example, we are investigating the absorption kinetics of moisture-regulating packaging made up of several layers of film. Moreover, we are increasingly focusing on biobased packaging materials such as cellulose or polylactic acid (PLA), which we are investigating with regard to their suitability for MAP (modified atmosphere packaging) and moisture-regulating packaging design. Using mathematical modelling, we develop tailor-made packagings for fresh produce, taking into account product respiration rates and the transfer dynamics of gases during their passage through the packaging film.

Optimised atmosphere for storage

The gas composition within the package can have a strong influence on the quality of the fruit. The use of packaging gases such as nitrogen or carbon dioxide creates optimised storage conditions within gas-tight packaging (such as Modified Atmosphere Packaging MAP or MAHP) - similar to the atmosphere in large storage halls with controlled atmospher (CA). This protective atmosphere slows down the ripening process and thus extends the shelf life of the products by days or even weeks while maintaining their high quality.

The plant's natural ripening hormone ethylene, even in the smallest traces, can cause undesirable rapid ripening and decomposition of fruit and vegetables. Removing ethylene from the storage atmosphere is one of the major challenges in the post-harvest period. Conventional techniques can only 'buffer' ethylene, but are unable to decompose it. We have developed a novel photocatalytic filter technology (using UV light and titanium dioxide as catalyst) for ethylene degradation to efficiently remove the undesirable ripening gas from the storage atmosphere.

New methods for post-harvest monitoring

For a better monitoring of product quality in post-harvest, we investigate and develop new methods and procedures for the automated analysis of quality parameters in real time. The focus of our research is on optical methods such as fluorescence or reflection spectroscopy, and also on new methods such as laser backscattering, which in the future could indicate changes in tissue structure and components of stored fruit. The analysis of the aromatic compounds (VOCs) in the headspace of packaged fresh products can also be an indicator of initially invisible quality changes.

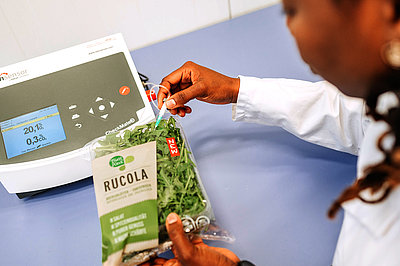

In order to record the physiological activity and thus the degradation processes of fresh products in the post-harvest quickly and easily, we have developed a small, flexible measuring device. O2, CO2, temperature and relative humidity sensors enable a continuous, non-invasive online monitoring of the effects of temperature, gas composition and storage time on the respiration rate and respiration quotient of the product. The modular sensor system is also suitable for continuous monitoring of environmental conditions in storage rooms and transport vehicles.

More on our research: WG Packaging and storage

Selected research projects on the topic

-

Food packaging is designed to protect the food through its supply chain, communicate to customers, and to ensure food quality, safety and optimal shelf life. Progress is now needed to secure its circularity, minimize fo…

-

This project aims to make use of the potential of integrative mathematical modeling to provide a comprehensive simulation approach for prediction of fresh produce physiological behavior with storage and packaging conditi…

-

Currently, the material of choice for trays for fresh food packaging like meat is mainly thermoformable plastic (PET, PP or PS) or plastic-paper composite materials. However, the recovery rate of those materials is still…

-

Packaging of fruit and vegetables is necessary to extend shelf life and increase safety. The use of plastic packaging is increasingly coming under criticism. An alternative can be the coating - a thin film on the surfac…

More projects on the topic ...

Selected publications

- Mahajan, P.; Pathak, N.; Grossi Bovi Karatay, G.; Ntsoane, L.; Jalali, A.; Keshri, N.; Rux, G.; Praeger, U.; Geyer, M. (2020): Recent advances on packaging and storage technologies for the preservation of fresh produce. Reference Module in Food Science. : p. 1-21. Online: https://doi.org/10.1016/B978-0-08-100596-5.23040-0

- Keshri, N.; Truppel, I.; Herppich, W.; Geyer, M.; Mahajan, P. (2021): Modular sensor-based respirometer for real-time monitoring of respiration rate. Acta Horticulturae. : p. 297-302. Online: https://doi.org/10.17660/ActaHortic.2021.1311.37

- Keshri, N.; Truppel, I.; Linke, M.; Geyer, M.; Weltzien, C.; Mahajan, P. (2021): Development of a Controlled-Ventilation Box for Modified-Atmosphere Storage of Fresh Produce. Foods. (12): p. 2965. Online: https://doi.org/10.3390/foods10122965

- Pathak, N.; Caleb, O.; Rauh, C.; Mahajan, P. (2019): Efficacy of photocatalysis and photolysis systems for the removal of ethylene under different storage conditions. Postharvest Biology and Technology. (January): p. 68-77. Online: https://doi.org/10.1016/j.postharvbio.2018.09.006

- Jalali, A.; Linke, M.; Geyer, M.; Mahajan, P. (2021): Integrative programming for simulation of packaging headspace and shelf life of fresh produce. MethodsX. : p. 101514. Online: https://doi.org/10.1016/j.mex.2021.101514

- Jalali, A.; Linke, M.; Mahajan, P. (2021): Model for simulation of gas, moisture and condensation dynamics in packaged fresh produce. Acta Horticulturae. : p. 263-272. Online: https://doi.org/10.17660/ActaHortic.2021.1311.33

Search for more publications on the topic ...