Smart, integrated biorefineries

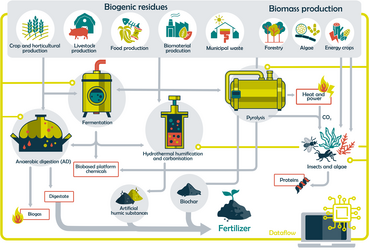

A boost for the circular economyValue creation without fossil raw materials? Reshaping our economic system to be based upon renewable, i.e. biological resources is the core to establish a sustainable, bio-based circular economy. That requires us to extend beyond primary production and to use our biological resources in an optimal manner. Smart, integrated biorefineries will be one of the key technologies for achieving that goal.

Modern biorefineries utilise a variety of different conversion processes. Farmers are harvesting biogas from the feces/manure of their dairy cattle via anaerobic fermentation, charcoal burners carbonise wood to biocharcoal and chemical companies are gaining lactic acid via fermenting leftover food which in return isn't just useful to the food economy itself but can also be used in order to produce bio plastics. All those processes have been well researched already and some are used on an industrial scale.

What smart, integrated biorefineries are able to achieve

We've developed the concept of smart, integrated biorefineries at ATB. Those biorefineries differ from more regular biorefineries due to them combining several processes. Our team of researchers has been able to discover that by combining several processes, strong synergies are being created. Those processes are not just accompanying each other but also optimise each other so that the biological starting material is fully utilised in the end.

Intelligent biorefineries are contributing directly to the protection of critical planetary boundaries, especially the protection of the climate, via maximising bio-based production, binding and storing carbon and minimising greenhouse gases. Thus, it's striving to completely avoid the further accumulation of unused waste and to achieve complete energy autonomy by converting all waste products into valuable products in their own right.

From conceptuality to reality

Thousands of different combinations of resources, process-parameters and conversion possibilities are imaginable when it comes to achieving an integrated and smart concept. Researching those possibilities solely via practical experimentation would be extremely costly – both in financial ways as well as time – and not realistically achievable within the limited timeframe remaining when it comes to fighting climate change. That's why we're using artificial intelligence, mechanical learning and digital twin-technologies in order to discover new and hidden synergies. These tools allow the development of biorefineries that can be fine-tuned to work with different types of biomass, significantly reduce production costs, minimise the strain on climate and nature in general and improve the circular economy.

The challenges and our approach to solution

The different conversion processes can be influenced via the activation of several parameters. Additionally, we want to use a large variety of both regional as well as seasonal biomass resources (up to 90). The different processes can further be combined with one another, which leads to an enormous amount of potential scenarios. Research merely driven forward via practical experimentation would require too high financial resources and too much time; thus we're using AI-controlled simulations to identify efficient approaches. As one of the preparation measures we're optimising the subsystems. By combining international industrial knowledge and research results of/about sensory, AI, digital twins and modeling technology, we allow for the development of adaptable and scalable intelligent bioreffineries. Those can work through a huge variety of scenarios in order for a sustainable bioeconomy within the planetary boundaries to be realised.

The opportunities

Agricultural and gardening wastes, byproducts of the food industry, biowastes from bins and textile wastes — every biological residual product has the ability to serve as the starting material for valuable materials within the process of conversion. They are an inevitable result of differing production and manufacturing processes and offer the potential of completing circular and recyclable processes. Due to them being able to be constructed and configured according to the local possibilities and prerequisites, they are strengthening the regional economic value creation and offer greater independence from exports of external raw materials and resources.

Pyrolysis

… converts dry biomass and residual materials under temperatures of 300 – 900 °C and under oxygen exclusion into warmth, chemicals, or biochar. Biochar can serve as an auxiliary material to improve soil quality and bind carbon within the soils for up to over 100 years (high recalcitrance index).

Hydrothermal carbonization

… converts wet biomass like food waste, manure, or algae under temperatures of 180 – 250°C and under pressure into hydrochar and nutrient-rich fluid. Hydrochar is a charcoal-like solid material that can be used as an energy carrier, auxiliary materials for soils, and carbon storage.

Anaerobic fermentation produces biogas, which can be used as an energy source. However, valuable organic compounds remain in the fermentation residue. Instead of using digestate/fermentation residues as fertilizer, as is usually done, we can convert it into artificial humic substances through hydrothermal humification. If humic substances are applied to agricultural soils instead of digestate/fermentation residues, they stabilise bacterial diversity and improve soil health. At the same time, humification of fermentation residues produces soluble organic compounds in the process liquid. If we feed these back into the anaerobic process during biogas production, we can double the methane yield.

The addition of biochar during fermentation breaks down process-inhibiting lignins. This significantly increases ethanol and lactic acid yield in the production of biochemicals. In addition, bio-heat and electricity generated during pyrolysis can be used for fermentation, which reduces dependence on external energy sources. The carbon dioxide emissions generated during pyrolysis can be captured and used for the cultivation of algae, which in turn serve as an alternative source of protein.

Another promising approach is the combination of anaerobic fermentation with pyrolysis, i.e. carbonization. The biochar acts as a catalyst and increases the efficiency of biogas production. At the same time, the biochar is enriched with nutrients. If the biochar is applied to the field, it can improve the soil and – depending on the process conditions – store carbon for more than a century.

Selected publications on the topic

- Marzban, N.; Psarianos, M.; Herrmann, C.; Schulz-Nielsen, L.; Olszewska-Widdrat, A.; Arefi, A.; Pecenka, R.; Grundmann, P.; Schlüter, O.; Hoffmann, T.; Rotter, V.; Nikoloski, Z.; Sturm, B. (2025): Smart integrated biorefineries in bioeconomy: A concept toward zero-waste, emission reduction, and self-sufficient energy production. Biofuel Research Journal. (1): p. 2319-2349. Online: https://doi.org/10.18331/BRJ2025.12.1.4

- Marzban, N.; Libra, J.; Hosseini, S.; Fischer, M.; Rotter, V. (2022): Experimental evaluation and application of genetic programming to develop predictive correlations for hydrochar higher heating value and yield to optimize the energy content. Journal of Environmental Chemical Engineering. (6): p. 108880. Online: https://doi.org/10.1016/j.jece.2022.108880

- Tkachenko, V.; Marzban, N.; Vogl, S.; Filonenko, S.; Antonietti, M. (2023): Chemical Insight into the Base-Tuned Hydrothermal Treatment of Side Stream Biomasses. Sustainable Energy & Fuels. : p. 769-777. Online: https://doi.org/10.1039/D2SE01513G

- Kohzadi, S.; Marzban, N.; Zandsalimi, Y.; Godini, K.; Amini, N.; Harikaranahalli Puttaiah, P.; Lee, S.; Zandi, S.; Ebrahimi, R.; Maleki, A. (2023): Machine learning-based modeling of malachite green adsorption on hydrochar derived from hydrothermal fulvification of wheat straw. Heliyon. (11): p. 21258. Online: https://doi.org/10.1016/j.heliyon.2023.e21258

- Ben Hamouda, A.; Boussadia, O.; Saussure, S.; Ellssel, P.; Schirrmann, M.; Hobart, M.; Young, G. (2022): Integrating agro-ecological practices and smart farming to improve agricultural production and insect pest control.

- Marzban, N.; Libra, J.; Rotter, V.; Herrmann, C.; Ro, K.; Filonenko, S.; Hoffmann, T.; Antonietti, M. (2024): Maximizing the value of liquid products and minimizing carbon loss in hydrothermal processing of biomass: an evolution from carbonization to humification. Biochar. : p. 44. Online: https://doi.org/10.1007/s42773-024-00334-1

- Höfle, D.; Sperber, S.; Marzban, N.; Antonietti, M.; Hoffmann, T.; Wicaksono, W.; Abdelfattah, A.; Berg, G. (2024): Artificial Humic Acid Diminishes the Effect of Drought on the Soil Microbiome. Journal of sustainable agriculture and environment. (4 (October 2024)): p. 1-11. Online: https://doi.org/10.1002/sae2.70034

- Psarianos, M.; Marzban, N.; Ojha, S.; Schneider, R.; Schlüter, O. (2024): Functional and bioactive properties of chitosan produced from Acheta domesticus with fermentation, enzymatic and microwave-assisted extraction. Sustainable Food Technology. : p. 1-9. Online: https://doi.org/10.1039/D4FB00263F

- Psarianos, M.; Schneider, R.; Altuntas, Ö.; Dimopoulos, G.; Taoukis, P.; Schlüter, O. (2024): Bioethanol production from edible insect excreta: a case study on frass from house crickets. Biofuel Research Journal. (4): p. 2211-2224. Online: http://dx.doi.org/10.18331/BRJ2024.11.4.2

- Herrmann, C.; Bose, R.; Neu, A.; Schneider, R.; Alexandri, M. (2024): Cascading valorization of defatted rice bran for lactic acid fermentation and biogas production. Biofuel Research Journal. : p. 2146-2167. Online: https://doi.org/10.18331/BRJ2024.11.3.2

- Babor, M.; Liu, S.; Arefi, A.; Olszewska-Widdrat, A.; Venus, J.; Sturm, B.; Höhne, M. (2025): Interpretable Domain Adaptation Enables Robust Lactic Acid Fermentation Monitoring from Waste. Results in Engineering. (March 2026): p. 108477. Online: https://doi.org/10.1016/j.rineng.2025.108477

- Arefi, A.; Sturm, B.; Babor, M.; Horf, M.; Hoffmann, T.; Höhne, M.; Friedrich, K.; Schroedter, L.; Venus, J.; Olszewska-Widdrat, A. (2024): Digital model of biochemical reactions in lactic acid bacterial fermentation of simple glucose and biowaste substrates. Heliyon. (19): p. 38791. Online: https://doi.org/10.1016/j.heliyon.2024.e38791

Search for more publications on this topic ...

Selected research projects on the topic

-

At the Leibniz Innovation Farm for Sustainable Bioeconomy, innovative concepts and technologies for a sustainable, circular bioeconomy will be developed and tested in future by combining agriculture with crop cultivation…

-

The overall objective of F4F2 is to create the conditions for an all-encompassing resilient society that ensures a sustainable supply of sufficient and healthy food through innovative solutions in the agrifood sector. Th…

-

At present, 60-70% of all soils are unhealthy in Europe as a result of land management practices, pollution, intensive agriculture, urbanisation, and the effects of climate change. Due to this and other biophysical const…

-

The goal of the project is the value-added processing of biomass by novel and advanced technologies to better exploit the environmental and economic potential of biogenic resources. A specific aim is to increase the effi…

-

The diversification of crop production systems in combination with a reduction in the use of agrochemicals and an increase in landscape complexity has the potential to promote biodiversity at the field and landscape scal…

-

Within the framework of the Joint Lab, the University of Osnabrück and the ATB jointly train doctoral students at the interface of agricultural science and artificial intelligence. A total of 40 scientists from both inst…

-

The ProtinA project is using crickets as an alternative source of protein to evaluate the potential of processing and treatment technologies, taking into account the nutritional value of selected foods. To this end, a pr…

-

Recent developments render the biobased sector a key player in European Economy providing a great impetus towards Circular Business Models of resource efficiency. Developments in biobased nanomaterials are coupled with b…

-

By 2030, Europe’s bioeconomy will grow significantly, with biorefineries as key drivers, converting waste and biomass into valuable products and energy for a circular economy. Challenges include fragmented knowledge, une…

-

The main objective of SPIN-FERT is to integrate optimised and validated innovations in soil management practices and improve peat-free substrates to enhance soil health in vegetable, fruit and ornamental crops. SPIN-FERT…

-

Functional integration in composite materials enables more cost-effective, resource-efficient, lighter and more reliable components and systems. One major disadvantage is the difficulty of recycling due to the multi-mate…

-

In the field of computer vision, Vision Foundation Models (VFM) have set new standards in visual tasks for understanding visual data, e.g. for image and object recognition, segmentation and classification, e.g. CLIP, SAM…

-

Modern chicken feeding is based on comprehensive studies of the nutrient requirements of specialized laying hens and broilers. It is necessary to adapt this knowledge to the specific needs of dual-purpose chickens in org…

-

The aim of the ‘AmmoCatCoat’ project is to research novel biomass-based carbons as a ruthenium (Ru) carrier material for industrial hydrogen production from ammonia (NH3 reforming). At ATB, suitable carbonaceous materia…

-

The aim of the project is to reduce nitrous oxide (N2O) and ammonia (NH3) emissions (N-emissions) in field vegetable production, mainly from crop residues with a high nitrogen (N) content. Removal of residues from the fi…

-

Project within the framework of the mobility funding programme of the Sino-German Center for Research Promotion with researchers from Sun Yat-sen University and the ATB or the University of Potsdam on the topic of Reliab…

-

The BeonNAT project aims to increase knowledge about the extraction of various organic products from wood species, trees and shrubs that are currently underutilized. The project evaluates the key aspects in the value cha…

-

The aim of the joint project is to develop a technically easy-to-implement process for the targeted reduction of greenhouse gas emissions (especially methane and nitrous oxide) during slurry and digestate storage by addi…

-

The aim of the joint project bio4value is to develop new types of gas separation membranes and membrane modules for more efficient biogas processing. The aim is to achieve a high quality of the separated material flows a…

-

High-quality animal proteins are difficult to replace largely by plant proteins in the feeding of carnivorous fish and omnivorous monogastric animals. The use of insect protein derived from by-products and residual strea…