Fruit production goes digital

Sensors, models and smart aidsDigital technologies are increasingly finding their way into fruit growing practice. Besides a more efficient use of resources, the aim is also to reduce environmental impact - while achieving high yields and top quality. Autonomous harvesting and care assistants will also make their way into the orchards.

In our research we develop methods for precision horticulture based on plant physiological models. On the other hand, we are working intensively on automated solutions that will help to reduce the workload on farms caused by labour-intensive care and harvesting work.

Data and models for a precise management

Methods of precision horticulture are designed to support producers in carrying out management measures such as fertilisation and irrigation - precisely and as needed. In order to obtain the most comprehensive information possible on the current state of plants, of soil and microclimate in the orchards, we use various stationary and mobile sensors. And we link the wide range of information in order to develop tailor-made recommendations for the zone- or tree-specific management of orchards. For example, knowledge of the spatial variability of an orchard can be used to derive production-relevant information for precise water management (Project AquaC+).

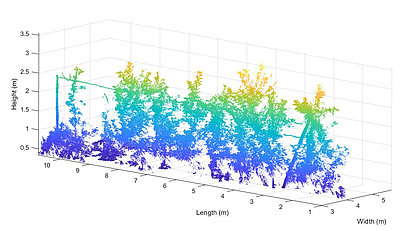

Mobile sensors - whether on tractors or drones - provide important information on the current status of plants and orchards. During passages and overflights, maps of the canopy volume or of the weed pressure are generated. This tree-specific or area-specific information is essential for precise plant protection with minimised application rates. Close-range sensors enable measurements directly on the plant: Miniaturised optical sensors can record current data on the water status and fruit ripening directly on the leaf or fruit and thus provide information for irrigation management and for the optimum harvesting time.

In our Fieldlab for Digital Agriculture in Marquardt we are testing remote and close-range sensors and also carry out aerial surveys of fruit trees.

Smart applications

We combine the findings from our basic research into practical applications. Here we present three examples.

An app supports fruit producers in harvesting cherries at the right time. To do this, it is sufficient to photograph with a smartphone individual cherries on the tree using a printed paper sheet for size referencing. The app analyses fruit size development and determines the best possible harvest date for marketing based on the variety and location-specific ripening pattern.. (App CHERRY HARVEST SIZE in Goolgeplay Store)

With a tree indivual mechanical thinning of the blossoms higher yields can be achieved with best fruit quality. A stereo camera mounted on the front of the tractor records the existing flower density for each individual tree. This information can be used to control the spinning speed of the rotating spindle brush, which mechanically strikes off flowers as it passes by. Depending on the number of flowers, the spindle rotates faster or slower. It removes more flowers, e.g. when passing a heavily flowering tree. (Project SmaArt)

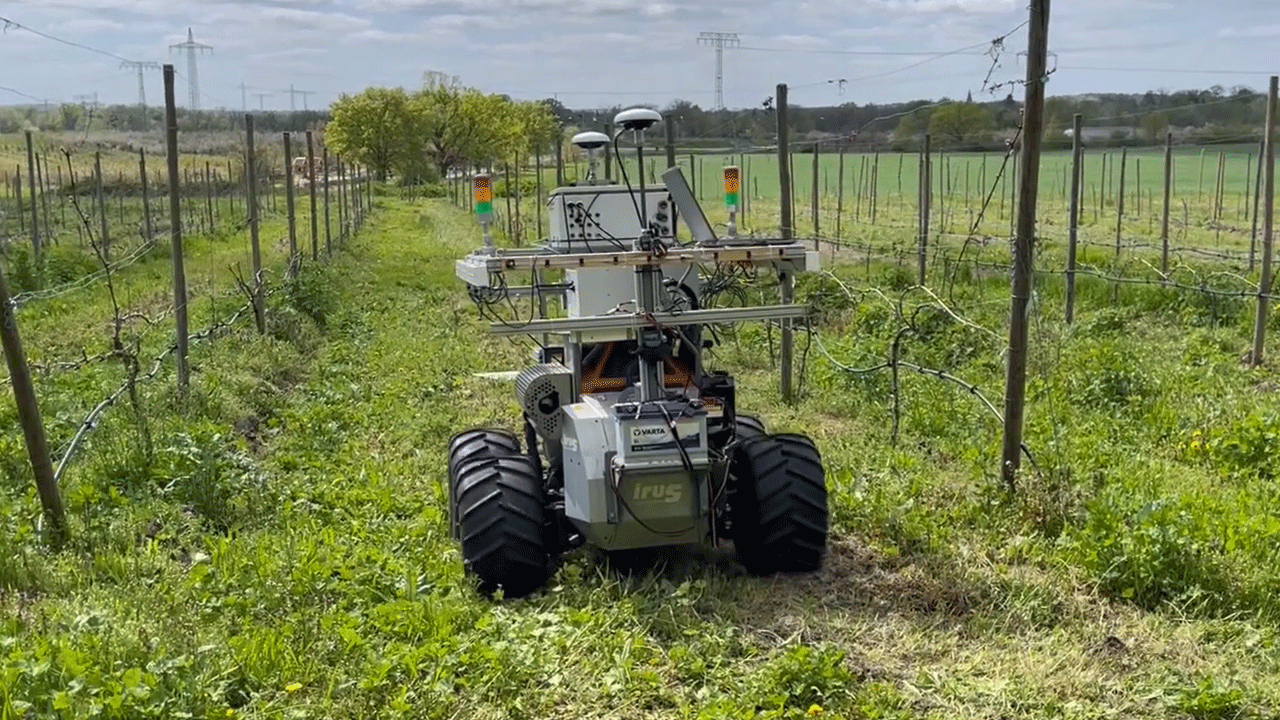

In the future, automated care and harvesting machinery could provide support for very labour-intensive and therefore costly production processes. In the SunBot project, for example, we are working on an energy-autonomous tractor-mowing unit that will in future autonomously be able to take care of the weeds in bush berry plants - even at night. The close cooperation between research, industry and practice aims at practicability and a fast transfer of results into practice. (sunbot.de)

Selected research projects related to this topic

-

The main goal of IRRIWELL is to test the implementation of a novel approach to estimate water requirements of fruit trees based on stomatal conductance with the aid of plant sensors and mechanistic physiological models. …

-

In the EIP Project Aqua C + effective data for water requirements for the cultivation of fruit crops be made available. Existing models of irrigation control will be tested and validated systematically under practica…

-

The aim of the collaborative project is to develop a modularized mobile system, which will enable an initial spatio-temporal high-resolution population monitoring (4D) of insect populations in orchards, in order to imple…

-

The aim of the MONIQUA project is to establish a digital monitoring system for the early detection and localisation of quarantine diseases in commercial fruit growing. On the basis of image recordings and machine learnin…

-

In the EIP project SunBot, a driverless, electrically operated tractor-unit combination of marketable and new components is being developed. It will be used in the future for herbaceous growth under the shrubs in berry c…

Search for more projects...

Selected publications

- Saha, K.; Tsoulias, N.; Weltzien, C.; Zude-Sasse, M. (2022): Estimation of Vegetative Growth in Strawberry Plants Using Mobile LiDAR Laser Scanner. Horticulturae. (2): p. 90. Online: https://doi.org/10.3390/horticulturae8020090

- Zare, M.; Drastig, K.; Zude-Sasse, M. (2020): Tree water status in apple orchards measured by means of land surface temperature and vegetation index (LST-NDVI) trapezoidal space derived from Landsat 8 satellite images. Sustainability. (1): p. 70. Online: https://doi.org/10.3390/su12010070

- Tsoulias, N.; Gebbers, R.; Zude-Sasse, M. (2019): Using data on soil ECa, soil water properties, and response of tree root system for spatial water balancing in an apple orchard. Precision Agriculture. : p. 1-27. Online: https://doi.org/10.1007/s11119-019-09680-8

- Tsoulias, N.; Paraforos, D.; Fountas, S.; Zude-Sasse, M. (2019): Estimating Canopy Parameters Based on the Stem Position in Apple Trees Using a 2D LiDAR. Agronomy. (9): p. 740. Online: https://doi.org/10.3390/agronomy9110740

- Penzel, M.; Pflanz, M.; Gebbers, R.; Zude-Sasse, M. (2021): Tree adapted mechanical flower thinning prevents yield loss caused by over thinning of trees with low flower set in apple. European Journal of Horticultural Science. (1): p. 86-89. Online: https://doi.org/10.17660/eJHS.2021/86.1.10

Search for more publications ...