Gentle processes for fresh products from harvest to consumption - to ensure healthy nutrition for both humans and animals

The programme area 'Healthy Foods' addresses complex scientific issues in the spectrum between primary production and processing of food and feed.

'Healthy foods', which are produced fairly taking into account environmental and animal welfare, include hitherto underutilized plant species such as legumes and pseudocereals, as well as alternative bioresources, e.g. land-cultivated macroalgae and insects.

Our research aims to minimize post-harvest losses, improve product quality and simultaneously increase resource and process efficiency embedded in the context of a circular bioeconomy. To this end, we develop innovative interdisciplinary approaches along the entire value chain and integrate side streams into bioeconomic process chains.

Following the concept of 'Quality by Design' in the optimization and development of sensors and control systems, we first analyze the respective system requirements and design the process based on this. The development of tailored physical, physicochemical and/or biological processes considers important ingredients and product properties as well as desirable or avoidable microbial systems. We also analyze environmental impacts in production and post-harvest, especially with regard to water, wastewater, energy, by-products and residues.

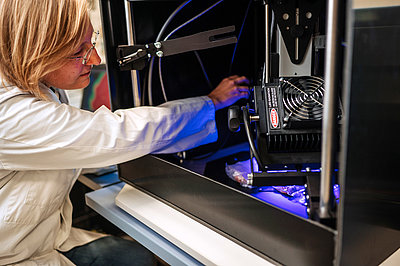

For our research, we have access to laboratory areas with high-end specialized equipment, including the freshness lab and microbiology laboratory.

Product properties and in-situ sensing

For the in-situ monitoring of the quality in perishable food products along the value chain, we develop sensor-based methods that allow us to analyze product properties non-destructively and to record process variables. In the field and post-harvest, we use methods including hyperspectral imaging, chlorophyll fluorescence spectroscopy, laser-induced multispectral backscatter analysis and Raman spectroscopy. The product information obtained is used in agronomic models as well as for the development of digital twins.

Dynamics of microbial communities

We develop methods for early and specific detection of microbial contamination in postharvest fresh produce. In this regard, we pursue both cultivation-dependent and cultivation-independent approaches based on the analysis of microbial DNA sequences. The characterization of microbial communities and their dynamics along the process chains from substrate to product will contribute to the application of methods for the targeted inactivation of pathogens or also for the promotion of desirable microorganisms.

Thermal and non-thermal processes for preservation and hygienization

The focus is on efficient, product-friendly solutions for the preservation of food and feed - from their fundamentals to their industrial implementation. We are investigating product-process interactions in drying as a fundamental thermal process in the preparation of bulk materials such as grain. Using apples as an example, we further develop the combination of process models with measured ingredient-specific reaction kinetics.

In the area of non-thermal treatment processes for sanitization, such as hydrostatic high pressure and low-temperature plasma, we are further expanding our expertise through upscaling and transfer to industrial applications. A newly established laboratory platform enables basic, large-scale experiments with pathogens in model processing chains.

Packaging and storage systems

We investigate the interactions between environmental conditions and product quality during cooling, storage and transportation of fresh food. We develop technologies for a tailored packaging or storage regime along the supply chain to reduce post-harvest food losses. In particular, our goal is to better understand the mechanisms of water vapor and condensation dynamics in packaged fresh produce and, on this basis, to develop optimized packaging in a moisture-regulating design, increasingly from bio-based materials such as cellulose or polylactic acid (PLA).

To the team of the programme area

Research projects

-

-

-

-

The overall objective of F4F2 is to create the conditions for an all-encompassing resilient society that ensures a sustainable supply of sufficient and healthy food through innovative solutions in the agrifood sector. Th…

-

The main objective of the NOVISHPAK project is to develop innovative biodegradable, antimicrobial and intelligent packaging films and edible coatings based on polysaccharides from seaweed, which are used to extend the sh…

More projects within the programme area

Publications of the programme area

- Mahajan, P.; Nur Hanani, Z.; Chaiwong, S. (2026): Moisture Condensation and Antifogging Films for Fresh Produce Packaging. Reference Module in Food Science. : p. 1-10. Online: https://doi.org/10.1016/B978-0-443-34158-8.00018-9 1.0

- Tayyab, M.; Sturm, B.; Khoshnam, F.; Delele, M.; Arefi, A. (2026): 3D Point Cloud based Optical Tracking of Dynamic Quality Degradation during Drying of Fruits and Vegetables. Journal of Food Engineering. : p. 113017. Online: https://doi.org/10.1016/j.jfoodeng.2026.113017 1.0

- Taheri Sedeh, H.; Hammerl, J.; Hertwig, S.; Schlüter, O. (2026): Bacteriophage-assisted non-thermal processing of foods: Challenges and innovative concepts to inactivate microbial pathogens. Current Opinion in Food Science. : p. 101380. Online: https://doi.org/10.1016/j.cofs.2026.101380 1.0

- Wicaksono, W.; Zukancic, E.; Zlatnar, M.; Suwanto, A.; Berg, G. (2026): Traditional fermented foods of Indonesia harbour functionally redundant but phylogenetically diverse taxa. FEMS Microbes. (xtag005): p. 1-13. Online: https://doi.org/10.1093/femsmc/xtag005 1.0

- Arefi, A.; Vilas, C.; Delele, M.; Först, P.; Gruber, S.; Kaveh, M.; Khoshnam, F.; Hashim, N.; Ali, M.; Zohrabi, S.; Tayyab, M.; Parmar, A.; Aradwad, P.; Ndisya, J.; Amjad, W.; Babor, M.; Mahn, A.; Sturm, B. (2025): Convergence of Digital Twins and food drying technology: How to bring the next generation of dryers to life!?. Journal of Food Engineering. (February 2026): p. 112770. Online: https://doi.org/10.1016/j.jfoodeng.2025.112770 1.0

- Tayyab, M.; Sturm, B.; Delele, M.; Arefi, A. (2025): Hyperspectral and 3D Point Cloud Imaging Unraveling of Physio-Chemical shifts during Drying of Purple Carrot and Golden Kiwifruit. Food Control. (January 2026): p. 111578. Online: https://doi.org/10.1016/j.foodcont.2025.111578 1.0

- Aradwad, P.; Raut, S.; Abdelfattah, A.; Rauh, C.; Sturm, B. (2025): Brewers spent grain: Unveiling innovative applications in the food and packaging industry. Comprehensive Reviews in Food Science and Food Safety. (3): p. 70150. Online: https://doi.org/10.1111/1541-4337.70150 1.0

- Aradwad, P.; Arefi, A.; Raut, S.; Abdelfattah, A.; Delele, M.; Rauh, C.; Sturm, B. (2025): Compositional dynamics, volatome profiling, and hyperspectral-based predictive modeling for quality monitoring of brewers spent grain during storage. Food Control. (February 2026): p. 111662. Online: https://doi.org/10.1016/j.foodcont.2025.111662 1.0

- Hoffmann, T.; Praeger, U.; Linke, M.; Büchele, F.; Neuwald, D.; Jedermann, R.; Geyer, M.; Sturm, B.; Mahajan, P. (2025): Influence of air flow rate on the cooling characteristics of a single and batch apple fruits. Thermal Science and Engineering Progress. (March 2025): p. 103257. Online: https://doi.org/10.1016/j.tsep.2025.103257 1.0

- Kalnar, Y.; Sonawane, A.; Weltzien, C.; Mahajan, P. (2025): Evaluating soda-lime adsorption and microcontroller-based system for the dynamic control of CO2 in a fresh produce storage box under varying temperature. Journal of Agriculture and Food Research. (June 2025): p. 101852. Online: https://doi.org/10.1016/j.jafr.2025.101852 1.0

More publications of the programme area