WG Packaging and storage

The objective of this working group is to develop an integrated system that combines sensors and mathematical models to optimize packaging and storage conditions for fresh produce. By leveraging sensor technology, mathematical modeling, and data-driven control strategies, the goal is to improve the quality and extend the shelf life of fresh produce during storage (see also 'Rethinking packaging').

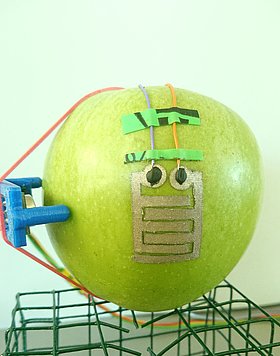

Respiration sensor for real-time monitoring of gases in fresh produce storage. Equipped with an optical O2 sensor (0-25% range) and two CO2 sensors (0.5% and 20% range), it provides crucial data on O2 and CO2 concentrations. Successfully used for fruit respiration monitoring in commercial apple storage, the modular system shows potential for in-situ monitoring and integration into RQ-based DCA storage. However, further development is needed to enhance efficiency, effectiveness, data analytics, and hardware integration.

Airflow sensor for measuring air speed between fruits stored in bulk bins. To optimize airflow and reduce costs in cooling agricultural produce, understanding the spatial distribution of airflow is crucial. Hence, an omnidirectional airflow sensor was developed to measure air speed between horticultural produce stored in bulk bins. This sensor enhances comprehension of airflow conditions near the stored produce, ultimately improving the quality of fruits and vegetables in cold storage.

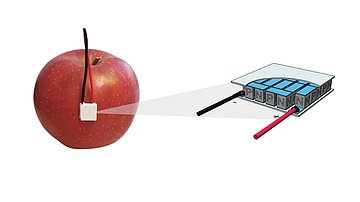

Condensation sensor for fruit cooling and cold storage: To maintain the quality of stored fruits, managing humidity and condensation is vital. A developed condensation sensor measures direct condensation on fruit surfaces. It utilizes a resistive, 0.1 mm thick electrically conductive film attached to the fruit surface. This wetness sensor studies water vapor condensation and evaporation stages on apple surfaces under different postharvest scenarios, including temperature fluctuations and re-warming. The next objective is to integrate live-sensor data with shelf-life models for optimal cooling and real-time condensation management in fruit storage and cold environments.

Heat flux sensor for measuring heat transfer during fruit cooling. It captures the initial heat flow from the food to the surroundings and monitors temperature fluctuations during long-term storage caused by compressor cycling and metabolic heat from the fruit. This real-time sensor, based on a Peltier element, enables understanding of the heat exchange between the fruit and the cooling system. The data provided by the sensor aids in modeling and designing new refrigeration systems, with the goal of extending food shelf life and achieving energy efficiency.

In fruit cooling, a digital transition is being explored to optimize long-term cold storage, especially for apples and pears. Traditional refrigeration systems are typically operated at partial load capacity, resulting in oversized designs based on simplified linear heat load calculations during the short cooling phase. Our work focuses on understanding heat transfer in fruits and large storage bins to calculate the transient heat load during the cooling phase. We also investigate the impact of cooling phase duration on product quality preservation. Furthermore, we explore the energy efficiency of future cooling systems using alternative refrigerants.

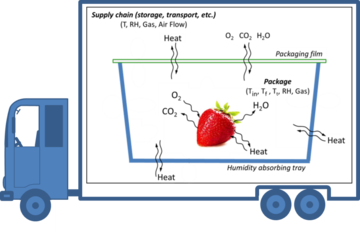

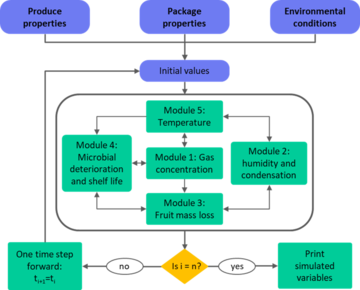

Mathematical modeling drives our packaging design process. It considers factors like gas and water vapor permeability, respiration rate, and transpiration of specific fruits. We also account for storage temperature, package size, product quantity, and optimal O2, CO2, and humidity conditions to minimize moisture condensation. Leveraging our engineering expertise, we've developed predictive mathematical models for fresh produce packaging design and shelf life. These models are applied to select packaging materials and undergo simulations and validation through lab-scale and commercial-scale trials across a range of products.

The Matlab code simulates package headspace and shelf life by integrating produce, package, and atmosphere properties through ordinary differential equations. This flexible simulation system reduces the need for costly and time-consuming experimental procedures when selecting optimal packaging materials for fresh produce. It aids in designing perforation size and number for equilibrium modified atmosphere packaging (EMAP), either alone or combined with materials having higher water transmission rates or active moisture absorbers. Furthermore, it predicts the shelf life of fresh produce under actual supply chain conditions. For more information, including the code download, please refer to the open-access paper by Jalali et al. (2021).

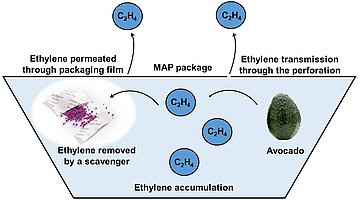

Model that simulates ethylene accumulation in fruit packaging. This integrative mathematical model considers ethylene transmission (through a perforated package), ethylene production (by fruit) and ethylene removal (by scavenger) in a fruit package. Using MATLAB, the model predicts ethylene accumulation in the package headspace based on various parameters related to the package, fruit, scavenger, and supply chain conditions. This analysis enables the optimization of packaging materials to extend the shelf life of fresh produce and minimize postharvest losses.

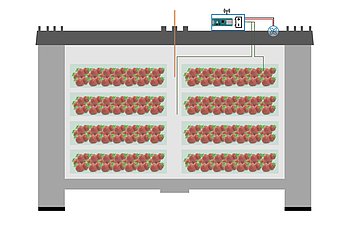

Integrating mathematical models, sensors, and electronic modes is an effective approach for real-time control of O2 and CO2 levels in storage or transport containers for fresh produce. A mathematical model that balances respiration rate and gas exchange through a perforated tube-blower assembly enables indirect gas control based on temperature. Thermocouples monitor‘s container temperature, triggering the air-blower to adjust its operation if deviations occur. The model estimates blower ON time to regulate O2 concentration by exchanging air between the container's inner and outer atmosphere. Currently, the concept is suitable for CO2-tolerant commodities with higher CO2 control (>15%). Further research is needed to implement this approach in real-world supply chains with variable temperature fluctuations.

Team of the WG

PhD Researchers:

Tuany Hoffmann

Yogesh Kalnar

Guest Scientists:

Manfred Linke

Dr. Reiner Jedermann